Engineering Plastics

Engineering plastics is a loosely defined term covering those thermoplastics and thermosets, with or without fillers, which exhibit superior mechanical, chemical, and thermal properties over a wide range of conditions, over and above the more commonly used standard or commodity plastics.

Typically, an engineering plastic, or advanced engineering plastic, is chosen for a range of enhanced physical properties that are required for a specific application. These properties may include: chemical resistance, wear resistance, dimensional stability, dielectric properties, or heat resistance.

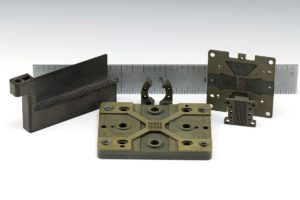

Example of plastic machining – cnc machine shops, precision machining part, machining nylon, machined components

Advanced engineering plastics are usually manufactured in low volume and may require significantly more process time during manufacturing; therefore, these materials are usually far more costly than are standard or commodity plastics.

For decades Mica-Tron Products Corp. has been machining all grades of engineering and advanced engineering plastics. We have the equipment, facilities, and expertise to perform CNC and manual milling, drilling, tapping, and turning of both thermoplastic and thermoset engineering plastics. In addition, we have an extensive selection of grinding equipment, incuding CNC Blanchard grinders, which allow us to hold tolerances not usually attainable by milling or turning.

Our extensive experience machining non-metallics has given us the opportunity to develop proprietary techniques which allow us to get the best possible yield from the more costly materials.

Our facilities, which are dedicated to the machining of non-metallics, include full dust collection to all equipment. (Dust-laden air is first filtered and then returned to the facility through large HEPA filters, which helps us keep our heating/cooling costs lower.) Also, the facility is climate controlled to help ensure dimensional stability and equipment accuracy. Grinding operations use deep bed filters to keep specially formulated, water-based coolants clean and free of tramp oils and contaminants. When our process requires high speed milling (milling above 15,000 RPM) we have tool holder balancing equipment, allowing us to achieve the best possible finishes and tolerances.

Above and beyond our facilities and equipment, we have countless years of experience designing tooling and fixtures that may be required to machine non-metallic parts. By trusting Mica-Tron Products Corp. to machine your most challenging components, you can minimize a multitude of risks. Confident in our hard-earned expertise, we welcome and strive to meet your most difficult challenges.

EXAMPLES OF STANDARD PLASTICS:

(Non-Critical, Low Stress Applications)

- Polystyrene (PS)

- Low Density Polyethylene (LDPE)

- High Density Polyethylene (HDPE)

- Polyvinyl chloride (PVC)

- Polypropylene (PP)

- Acrylonitrile butadiene styrene (ABS)

EXAMPLES OF ENGINEERING PLASTICS:

(General purpose structural, good chemical resistance, general purpose bearing and wear applications)

- Polymethyl methacrylate (PMMA) – Acrylic

- Polyphenylene oxide, modified (PPO) – Noryl®

- Polycarbonate (PC) – Lexan®

- Ultra high molecular weight Polyethylene (UHMW)

- Polyamide (PA) – Nylon

- Polyoxymethylene (POM) – Acetal, Delrin®

- Polyethylene Terephthalate (PET-P) – Ertalyte®

EXAMPLES OF ADVANCED ENGINEERING PLASTICS:

(Superior chemical resistance, higher temperature capability, greater dimensional stability, good wear resistance)

- Polysulfone (PSU)

- Polyphenylsulfone (PPSU) – Radel®

- Polyetherimide (PEI) – Ultem®

- Polytetrafluoroethylene (PTFE) – Teflon®

- Mica Filled PTFE – Fluorosint®

- Polyphenylene sulfide (PPS) – Techtron®, Ryton®

- Polyetheretherketonr (PEEK)

- Polyamide-imide (PAI) – Torlon®

- Polyimide (PI) – Vespel®, Meldin®

- Polybenzimidazole (PBI) – Celazole®